You have no items in your shopping cart.

In our current era of ever-increasing energy costs and growing environmental awareness, lighting solutions can be a significant factor in both utility bills and ecological footprint. At Jarvis Lighting, we believe in providing our customers with the best solutions available, which is why we emphasize the superiority of LED technology. But for businesses that have fluorescent lighting fixtures installed, making the switch might seem daunting.

If you're in such a predicament, fret not. Converting fluorescent lighting fixtures to LEDs using retrofit kits is a worthwhile upgrade that provides several benefits, including increased energy efficiency, superior lighting quality, longer lifespan, and lower maintenance costs.

In this comprehensive guide, we'll help you understand the intricacies of fluorescent and LED lighting, the feasibility and process of conversion, and the role of retrofit kits. By the end, you'll be well-equipped to make the shift to LEDs – a journey towards cost savings, superior lighting, and environmental care.

How Fluorescent Lighting Works

Fluorescent lighting relies on a very different principle compared to traditional incandescent bulbs. Rather than heating a filament, a fluorescent lamp contains a gas, generally mercury vapor, which emits ultraviolet light when energized by an electric current. This UV light strikes the phosphor coating inside the tube, causing it to fluoresce, or emit visible light.

Common Issues and Limitations of Fluorescent Lighting

While fluorescent lighting is a step up from incandescent bulbs in terms of energy efficiency, it has some limitations:

- Flickering and Buzzing: Aging fixtures or issues with the ballast or starter can lead to a noticeable flicker and annoying buzzing noise.

- Color Quality: Fluorescent lights can distort color perception, making environments appear dull or washed out.

- Energy Inefficiency: Although better than incandescents, fluorescents still consume more energy than LEDs.

- Environmental Concerns: The mercury within fluorescent lamps is a hazardous substance, making safe disposal a concern.

Advantages of LED Lighting

1. Energy Efficiency and Cost Savings

LED lighting is significantly more energy-efficient than fluorescent lighting. LEDs can produce the same amount of light as fluorescents while using less than half the energy. This results in significant cost savings on utility bills over the lifespan of the LEDs, offsetting the higher upfront cost.

2. Longevity and Durability

LEDs have an impressively long lifespan, often exceeding 50,000 hours—five times longer than the average lifespan of a fluorescent tube. Moreover, LEDs are solid-state devices, meaning they are less susceptible to damage from shock or vibration, making them more durable than fluorescent tubes.

3. Enhanced Lighting Quality

LEDs provide superior color rendering, meaning they represent colors more accurately under their light. They also offer better directional control, reducing the need for reflectors and diffusers that can trap light, thus ensuring more light reaches the intended area.

4. Environmental Benefits

LEDs are a green choice, free from any harmful substances, so they pose no risks when it comes to disposal. In addition, they convert nearly all energy into light, significantly reducing heat emissions and consequently lowering your cooling costs.

Steps to Convert Fluorescent Lighting Fixtures to LED with Retrofit Kits

Step 1 - Assess the Feasibility of Converting Fluorescent to LED

1. Evaluate Existing Fluorescent Lighting Fixtures

Before embarking on the conversion journey, it's essential to evaluate your current fluorescent fixtures. Determine their type (T12, T8, T5), their wattage, and the condition they're in. Consider factors like the fixture's age, condition, and location. A poorly located or old fixture may warrant replacement rather than retrofitting.

2. Identify Compatibility Issues and Potential Challenges

Not all fluorescent fixtures can be easily converted to LED, and not all situations are suited for conversion. You may encounter fixtures with odd shapes or sizes that may not have corresponding LED retrofit kits. Additionally, if you have an older building with outdated wiring, retrofitting could be more challenging.

3. Determine the Cost-Effectiveness of the Conversion

While LED lighting is more energy-efficient, you should still consider the initial cost of retrofit kits and labor versus the projected energy savings. To do this, calculate your current energy consumption and compare it with the potential energy use after conversion. Take into account the lifespan of the LEDs and the cost savings from less frequent replacements.

Step 2 - Prepare for the Conversion

1. Safety Precautions and Equipment Needed

The conversion process involves working with electrical fixtures, so safety must be a top priority. Always turn off power to the fixture before starting, use insulated tools, and wear safety glasses and gloves. It would be wise to have a fire extinguisher nearby, just in case.

2. Gather the Necessary Tools and Materials

You'll need a few basic tools to carry out the conversion: a ladder, a screwdriver, wire strippers, wire nuts, and possibly a voltage tester. Of course, you'll also need your selected LED retrofit kits.

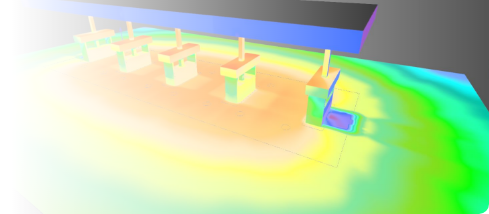

3. Conduct a Thorough Lighting Audit

Before purchasing your retrofit kits, conduct a lighting audit. Note the number, type, and wattage of your existing fixtures. Measure the brightness (in lumens) you require in each area. This will guide you in choosing the correct retrofit kits and help ensure you achieve the desired lighting levels post-conversion.

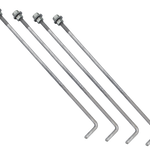

Step 3 - Choose the Appropriate LED Retrofit Kits

This is where Jarvis Lighting shines. We offer a range of high-quality LED retrofit kits that can help simplify your transition from fluorescent to LED. Our kits are designed to provide an easy and efficient way to convert existing fluorescent fixtures into energy-saving LED fixtures, maintaining or even enhancing the lighting levels.

When choosing a retrofit kit, consider the size and type of your existing fixtures, the required light output, and any specific needs such as dimming functionality. Our expert team at Jarvis Lighting is always on hand to provide personalized advice and ensure you select the most suitable retrofit kits for your specific needs.

Browse our collection of LED retrofit kits here: https://www.jarvislighting.com/collections/indoor-retrofit-kits

Step 4 - Follow the Installation Instructions Provided by Your Retrofit Kit Provider

Each Jarvis Lighting LED retrofit kit comes with detailed instructions to guide you through the conversion process. It's crucial to follow these instructions carefully. Remember, safety first—always disconnect power before beginning and consider hiring a professional electrician if you're unsure about anything.

Overview of the General Installation Process

Here's an overview of the process, but remember, always follow the specific instructions provided with your Jarvis Lighting retrofit kit.

1. Disconnect or Turn off Power Before Installation

This is an essential safety step. Always switch off the power at the circuit breaker before you begin working on any electrical fixture.

2. Remove the Existing Fluorescent Tubes

With the power off, carefully remove the fluorescent tubes. Be mindful that these contain mercury and should be disposed of properly.

3. Remove the Fluorescent Ballast

Once the tubes are removed, you will see the fluorescent ballast. Unscrew and disconnect it, carefully taking note of the connected wires. Remember, some older ballasts contain PCBs (polychlorinated biphenyls), which are considered hazardous waste and should be disposed of accordingly.

4. Remove the Tombstones and Tray (If Necessary)

In some retrofit scenarios, it may be necessary to remove the tombstones—the holders for the fluorescent tubes—and the tray that houses the ballast. This depends on the retrofit kit you've chosen and the specific instructions provided. Some LED retrofit kits are designed to work with the existing tombstones, while others require their removal.

5. Make All Necessary Wiring Connections

This is a crucial part of the retrofit process. Each retrofit kit will have specific wiring instructions. In general, however, you'll be connecting the LED driver to the existing power supply wires. Use wire nuts to secure these connections, and make sure no bare wire is exposed.

6. Turn the Power Back On and Test the Installation

After everything is connected and secured, it's time to restore power and test the installation. If everything has been done correctly, your LED lights should light up, providing a better quality, more energy-efficient lighting solution.

Jarvis Lighting: Easy and Cost-Effective LED Retrofit Kits

Converting your existing fluorescent fixtures to LED lighting is a big step towards improving your lighting quality, lowering your energy costs, and enhancing your environmental stewardship. It can seem like a daunting task, but with Jarvis Lighting, it doesn't have to be.

At Jarvis Lighting, we offer a range of LED retrofit kits that can convert a wide variety of fluorescent fixtures to LED. Our kits are easy to install and designed to last, ensuring that your investment in LED technology pays off handsomely in the long run.

But our commitment to your lighting needs doesn't end with providing high-quality products. We also believe in empowering our customers with knowledge and offering the support they need to make the conversion process as smooth as possible. Whether you're an electrician tasked with upgrading an office building's lighting, or a business owner looking to improve your storefront's illumination, we're here to help.

Discover our LED retrofit kits here: https://www.jarvislighting.com/collections/indoor-retrofit-kits