You have no items in your shopping cart.

- Catalog Download

- Find a Distributor

Application Guide

Warehouse Lighting Fixtures

Shop energy-efficient warehouse lighting fixtures at Jarvis Lighting. Our LED high bay lights and linear fixtures provide bright and reliable illumination for your space, improving safety and productivity. Browse our collection for quality lighting solutions for your warehouse.

Warehouse Lighting Fixtures

Wattage Range: 80-220W

Lumens Range: 12,000-33,000lm

The HBL-A series is a dependable and affordable solution for a wide variety of high bay lighting applications including replacing HID and linear fluorescent high bay lights. Featuring optics specifically...

LED Linear High Bay Light White HBL-A Series

Warehouse Lighting Fixtures

Wattage Range: 100-240W

Lumens Range: 15,000-36,000lm

An LED light perfect for industrial, manufacturing, or commercial settings. This A51-A series is designed for a wide variety of lighting needs and can be used for many locations.

LED Round High Bay Black A51-A Series - Dim-to-Off

Warehouse Lighting Fixtures

Wattage Range: 100-240W

Lumens Range: 15,000-36,000lm

An LED light perfect for industrial, manufacturing, or commercial settings. This A51-A series is designed for a wide variety of lighting needs and can be used for many locations.

LED Round High Bay Black A51-A Series - Dimming Only

Warehouse Lighting Fixtures

Wattage Range: 24-64W

Lumens Range: 3,120-8,525lm

This linear strip light fixture has a wide 120° beam angle which allows for an excellent solution for low bay lighting applications. This product is designed to replace existing fluorescent...

LED Linear Strip Light LSL2 Series

Warehouse Lighting Fixtures

Wattage Range: 24-40W

Lumens Range: 3,120-5,205lm

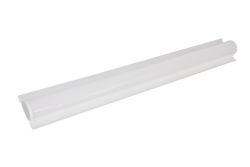

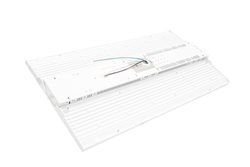

This sleek linear strip retrofit kit is compatible with many linear fluorescent light fixtures, including T8 and T12 fixtures. Built for lighting fast installations, its unique design creates bright even...

SRK Series LED Linear Strip Retrofit Luminaire

Warehouse Lighting Fixtures

Wattage Range: 24-40W

Lumens Range: 3,120-5,205lm

The Jarvis SRK-N Series LED Linear Strip Retrofit is a sleek, adjustable, and energy-efficient solution for upgrading existing HID and fluorescent fixtures. It features a durable stamped steel housing, a...

SRK-N Series LED Linear Strip Retrofit Luminaire

Warehouse Lighting Fixtures

Wattage Range: 80-220W

Lumens Range: 12,000-33,000lm

The HBL-A series is a dependable and affordable solution for a wide variety of high bay lighting applications including replacing HID and linear fluorescent high bay lights. Featuring optics specifically...

LED Linear High Bay Light White HBL-A Series - Selectable Wattage and CCT

Warehouse Lighting Fixtures

Wattage Range: 100-240W

Lumens Range: 15,000-36,000lm

The A51-A-G2 Series LED High Bay Luminaire is designed for easy installation. Its UFO design and impact-resistant lens ensure durability and maximum illumination. Compatible with Jarvis Link networked lighting control...

LED Round High Bay Black A51-A-G2 Series

Warehouse Lighting Fixtures

Wattage Range: 80-220W

Lumens Range: 12,000-33,000lm

The Jarvis HBL-SC Series LED High Bay Light offers 165W and 22,630 lumens for powerful lighting. Easy to install with built-in controls and high efficiency. Perfect for large spaces, it...

Jarvis HBL-SC Series LED High Bay Light - 165W, 22,630 lm, 5000K, Easy Install, Energy Efficient

Warehouse Lighting Fixtures

The Jarvis Lighting LHB-DCH Series LED Diecast Linear High Bay delivers efficient and versatile lighting for industrial and commercial applications. Featuring adjustable wattage and color temperature options, this high bay...

Jarvis Lighting LHB-DCH Series LED Diecast Linear High Bay - Adjustable Output & Color Temperature, Z10 Ready

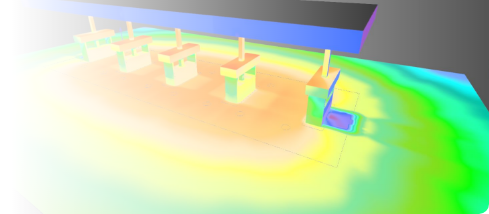

Warehouse Lighting

Warehouse lighting is essential for industrial spaces, ensuring visibility, productivity, and safety. These lighting systems cater to unique needs like loading, unloading, and inventory management. Energy-efficient LED lights, smart control systems, and motion sensors contribute to performance and cost-effectiveness. High-quality warehouse lighting improves operations, reduces costs, and creates a comfortable work environment.

Best Practices

Design a well-planned warehouse lighting layout

Best Practices

Minimize glare and shadows in warehouse lighting

Best Practices

Implement warehouse lighting controls

Best Practices

Opt for color temperature and color rendering index (CRI) appropriate for warehouse tasks

Frequently Asked Questions

The best color temperature for warehouse lighting is between 4000K and 5000K. This range of color temperatures produces a cool white light that is ideal for warehouse environments. Cool white light helps to reduce eyestrain and create a productive work environment.

The best lumen output for warehouse lighting depends on the size of the warehouse and the type of products being stored. For a small warehouse with low ceilings, a lumen output of 50 lumens per square foot may be sufficient. For a large warehouse with high ceilings, a lumen output of 100 lumens per square foot may be necessary.

There are several ways to save money on warehouse lighting, including:

- - Using energy-efficient lights, such as LED lights.

- - Installing motion sensors to turn lights off when they are not in use.

- - Using dimmers to reduce light levels when they are not needed.

- - Maintaining lights regularly to keep them operating at peak efficiency.

Consider illumination level, energy efficiency, lighting uniformity, color rendering index (CRI), lifespan, and fixture durability. Also, factor in maintenance costs, controls integration, and adherence to relevant regulations.

LED high bay fixtures are the ideal choice for warehouses, providing even illumination. Consider ceiling height, activity type, DLC certification, adjustable beam angles, and lighting controls.

Yes, there may be regulations or guidelines that need to be followed when upgrading warehouse lighting. For example, some municipalities or states have energy codes or standards that mandate certain lighting levels or energy efficiency requirements for commercial buildings. Additionally, OSHA (Occupational Safety and Health Administration) has guidelines for workplace lighting to ensure safe working conditions. It's important to research and comply with any applicable regulations or guidelines when upgrading warehouse lighting to avoid penalties and ensure the safety and efficiency of the space.