You have no items in your shopping cart.

- Catalog Download

- Find a Distributor

Application Guide

Industrial Lighting Fixtures

Our extensive range of industrial lighting solutions is designed to cater to a variety of applications, including warehouses, manufacturing facilities, workshops, and more. We understand the importance of reliable, energy-efficient, and durable lighting in creating a safe and productive work environment. Browse our comprehensive collection and find the perfect lighting solution tailored to meet the unique requirements of your industrial space.

Industrial Lighting Fixtures

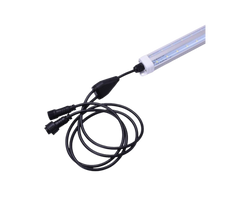

Wattage Range: 20-30W

The RLED-G2 Series is a bright and energy efficient vertical cooler door light fixtures. Driverless design plus included cables and quick connectors make for an easy and professional installation. LEDs...

LED Cooler or Refrigerator Light - 4, 5 or 6 feet RLED-G2 Series

Industrial Lighting Fixtures

Wattage Range: 80-220W

Lumens Range: 12,000-33,000lm

The HBL-A series is a dependable and affordable solution for a wide variety of high bay lighting applications including replacing HID and linear fluorescent high bay lights. Featuring optics specifically...

LED Linear High Bay Light White HBL-A Series

Industrial Lighting Fixtures

Wattage Range: 24-64W

Lumens Range: 3,120-8,525lm

This linear strip light fixture has a wide 120° beam angle which allows for an excellent solution for low bay lighting applications. This product is designed to replace existing fluorescent...

LED Linear Strip Light LSL2 Series

Industrial Lighting Fixtures

Wattage Range: 100-240W

Lumens Range: 15,000-36,000lm

An LED light perfect for industrial, manufacturing, or commercial settings. This A51-A series is designed for a wide variety of lighting needs and can be used for many locations.

LED Round High Bay Black A51-A Series - Dim-to-Off

Industrial Lighting Fixtures

Wattage Range: 100-240W

Lumens Range: 15,000-36,000lm

An LED light perfect for industrial, manufacturing, or commercial settings. This A51-A series is designed for a wide variety of lighting needs and can be used for many locations.

LED Round High Bay Black A51-A Series - Dimming Only

Industrial Lighting Fixtures

Wattage Range: 24-40W

Lumens Range: 3,120-5,205lm

This sleek linear strip retrofit kit is compatible with many linear fluorescent light fixtures, including T8 and T12 fixtures. Built for lighting fast installations, its unique design creates bright even...

SRK Series LED Linear Strip Retrofit Luminaire

Industrial Lighting Fixtures

Wattage Range: 24-40W

Lumens Range: 3,120-5,205lm

The Jarvis SRK-N Series LED Linear Strip Retrofit is a sleek, adjustable, and energy-efficient solution for upgrading existing HID and fluorescent fixtures. It features a durable stamped steel housing, a...

SRK-N Series LED Linear Strip Retrofit Luminaire

Industrial Lighting Fixtures

Wattage Range: 80-220W

Lumens Range: 12,000-33,000lm

The HBL-A series is a dependable and affordable solution for a wide variety of high bay lighting applications including replacing HID and linear fluorescent high bay lights. Featuring optics specifically...

LED Linear High Bay Light White HBL-A Series - Selectable Wattage and CCT

Industrial Lighting Fixtures

Wattage Range: 100-240W

Lumens Range: 15,000-36,000lm

The A51-A-G2 Series LED High Bay Luminaire is designed for easy installation. Its UFO design and impact-resistant lens ensure durability and maximum illumination. Compatible with Jarvis Link networked lighting control...

LED Round High Bay Black A51-A-G2 Series

Industrial Lighting Fixtures

Wattage Range: 80-220W

Lumens Range: 12,000-33,000lm

The Jarvis HBL-SC Series LED High Bay Light offers 165W and 22,630 lumens for powerful lighting. Easy to install with built-in controls and high efficiency. Perfect for large spaces, it...

Jarvis HBL-SC Series LED High Bay Light - 165W, 22,630 lm, 5000K, Easy Install, Energy Efficient

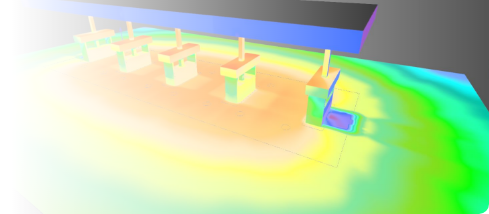

Industrial Lighting

Industrial lighting encompasses durable, energy-efficient fixtures designed for demanding environments like warehouses, factories, and workshops. These solutions prioritize safety, productivity, and cost-effectiveness, catering to the specific needs of each application. High-quality industrial lighting options include LED high bay lights, linear fixtures, and floodlights, offering reliable and long-lasting illumination for various industrial settings.

Best Practices

Ensure adequate illumination by selecting the correct lumen output and color temperature for specific tasks and areas within the facility.

Best Practices

Opt for fixtures with high ingress protection (IP) ratings to withstand harsh industrial environments and protect against dust and moisture.

Best Practices

Prioritize safety by selecting industrial lighting fixtures with features like shatter-resistant lenses and explosion-proof designs.

Best Practices

Consider adjustable and dimmable fixtures to allow customization of lighting levels based on changing needs.

Frequently Asked Questions

To determine the appropriate lumen output, consider factors such as the size and height of the space, the tasks being performed, and the desired light levels. As a general rule, you can calculate the needed lumens by multiplying the square footage of the area by the recommended foot-candles (light level) for the specific task. For instance, a warehouse may require 10-20 foot-candles, while precision tasks may need 50-100 foot-candles.

Industrial LED lighting is versatile, used in applications such as general lighting, task lighting, high/low bay lighting, outdoor area lighting, emergency lighting, explosion-proof lighting, machine lighting, inspection lighting, and signage/wayfinding. These lights enhance visibility, productivity, and safety in various settings, including warehouses, manufacturing facilities, and hazardous environments. LED lights provide energy-efficient, durable, and bright illumination, making them ideal for diverse industrial applications.

The color temperature, measured in Kelvins (K), impacts the appearance and perceived warmth or coolness of the light. In industrial settings, cooler color temperatures (4000K-5000K) are often preferred, as they provide bright and crisp illumination, enhancing visibility and reducing eye strain.

Industrial LED lights generally have low maintenance requirements due to their long lifespans and durable construction. However, it's essential to periodically inspect and clean the fixtures to ensure optimal performance, especially in environments with high dust or moisture levels. Dust and debris should be removed with a soft brush or cloth, and any accumulated moisture should be wiped away with a dry cloth. Always ensure the fixtures are switched off and cool to the touch before cleaning. Additionally, periodically check for any signs of wear or damage, such as loose connections, flickering, or dimming, and address these issues promptly to maintain optimal lighting performance and safety in your industrial space.

Many industrial LED lights are dimmable, allowing for greater control over light levels and energy consumption. However, it's essential to check the product specifications for compatibility with dimming systems to avoid issues like flickering or reduced lifespan.

Yes, hazardous location lighting in industrial spaces must comply with regulations and standards, such as those established by the National Electrical Code (NEC) and the International Electrotechnical Commission (IEC). These regulations classify hazardous locations based on the presence of flammable gases, dust, or fibers and require the use of specially designed and certified lighting fixtures, such as explosion-proof or intrinsically safe LED lights.